Hand knotted carpets represent the pinnacle of authenticity, durability, and luxury in the global rug industry. For discerning importers, interior designers, retailers, and hospitality buyers, these aren’t merely floor coverings—they’re investment pieces that must justify their value, meet rigorous compliance standards, and arrive precisely when promised.

At Scalane International, we serve as your factory-direct hand knotted carpet export partner from India—where centuries-old artisanal craftsmanship meets modern export infrastructure, comprehensive documentation, and logistics excellence. Whether you’re sourcing for the USA, Europe (Germany, UK), the Middle East, or Australia, we help global buyers access authentic hand knotted carpets with transparent technical specifications, HS code 5701 classification guidance, and clearly defined MOQ and lead time frameworks.

Global Hand Knotted Carpet Exporter for B2B Buyers

Who Our Hand Knotted Carpets Are Designed For

We specialize in serving B2B buyers who demand reliable, repeatable quality alongside a professional export experience:

- Interior designers and design studios specifying custom hand knotted rugs for distinguished residential and hospitality projects

- Retail carpet and flooring stores curating premium and luxury hand knotted rug collections that command attention

- Online retailers and marketplaces requiring consistent quality, standardized product data, and publication-ready imagery

- Hotels, resorts, spas, and hospitality chains seeking durable, compliant carpets for guest rooms and public spaces that withstand the test of time

- Wholesale distributors and regional aggregators building carefully curated, market-specific hand knotted assortments

- Project buyers and contractors supplying corporate offices, luxury villas, and institutional spaces with statement pieces

We recognize that each segment brings distinct requirements—from design flexibility and KPSI levels to documentation precision, compliance adherence, and protective packaging.

Countries We Export Hand Knotted Carpets To

Our hand knotted carpets are crafted in India and exported worldwide under HS code 5701 (Carpets and other textile floor coverings, knotted, whether or not made up). We partner closely with buyers across:

- USA and Canada – wholesale importers, distinguished rug galleries, and innovative e-commerce brands

- Europe – particularly Germany, France, Netherlands, Italy, and throughout the EU region

- United Kingdom – with post-Brexit compliance and documentation expertise

- Middle East – UAE, Saudi Arabia, Qatar, Kuwait, Bahrain, and beyond

- Australia & Oceania – importers, retailers, and project buyers seeking quality and reliability

- Emerging markets in Africa, Latin America, and Southeast Asia

Our experienced export team handles complete documentation, coordinates seamlessly with freight forwarders, and navigates country-specific requirements—ensuring your hand knotted carpets arrive with minimal friction and maximum confidence.

What Are Hand Knotted Carpets? (Complete Buyer-Friendly Overview)

Hand knotted carpets are created entirely by hand on a loom, with each individual knot tied meticulously around the warp yarns. This deliberate, time-intensive process is precisely what grants these rugs their exceptional longevity, distinctive character, and commanding value in international markets.

How Hand Knotted Carpets Are Made – Step-by-Step Process

1. Design & Mapping

A detailed design map is developed, capturing every motif, color transition, and knot position. For custom projects, this aligns seamlessly with your moodboards, CAD layouts, and specified color palettes.

2. Yarn Selection & Dyeing

Premium-grade wool, silk, or refined wool–silk blends are carefully selected. Yarns are dyed using either superior synthetic or natural dyes, depending on the collection and your preferences, with controlled dye lots ensuring color consistency across production runs.

3. Loom Setup

Cotton, wool, or blended warps are precisely tensioned on the loom. The design map is positioned where weavers can reference it throughout the creation process.

4. Knotting

Each knot is tied individually by hand around the warp threads. Depending on KPSI (knots per square inch), a single hand knotted carpet can require anywhere from several weeks to many months to complete.

- Lower KPSI, larger-scale design: expedited weaving, well-suited for high-traffic commercial applications

- High KPSI, intricate detail: extended weaving time, ideal for premium and luxury market segments

5. Trimming & Shearing

Once knotting reaches completion, the pile is trimmed to the specified height and sculpted to enhance pattern clarity and visual definition.

6. Washing & Finishing

Carpets undergo thorough washing to eliminate residues, enhance sheen (especially pronounced in wool–silk pieces), and stabilize colors permanently. Final finishing includes stretching, edge binding, and meticulous inspection.

7. Final Quality Check & Packing

Every piece is rigorously inspected for design accuracy, dimensional tolerance, color uniformity, and structural integrity before being carefully packed for export.

Hand Knotted vs Hand Tufted vs Machine Made – Key Differences

For importers and retailers, understanding these distinctions is essential:

Hand Knotted Carpets

- Individually tied knots, elevated KPSI, extended production timeline

- Typically higher price positioning, but substantially longer lifespan

- Exceptional resale value and compelling brand storytelling potential

Hand Tufted Carpets

- Created using a tufting gun with backing material

- Accelerated production, competitive pricing, effective for mid-market positioning

- Often deployed where rapid rollout and price sensitivity are paramount

Machine Made Carpets

- Produced on power looms with very rapid output

- Accessible cost, consistent uniformity but diminished “artisanal” perception

We position hand knotted carpets as the premier tier in your assortment—ideal for luxury customers, aspirational interiors, and long-term investment buyers. To build a comprehensive portfolio, we can complement this with hand tufted or other constructions as your market demands.

Why Hand Knotted Carpets Are Valued by Importers & Designers

- Exceptional durability and lifespan when properly maintained

- Greater design depth achieved through high knot density and nuanced color detailing

- Compelling storytelling—artisanal heritage, handmade authenticity, cultural legacy

- Enhanced margin potential for retailers driven by both perceived and genuine value

- Seamless alignment with premium and luxury brand positioning across global markets

Technical Specifications & Quality Grading (KPSI, Materials, Standards)

Technical transparency builds lasting trust with buyers and importers. For every hand knotted program, we provide comprehensive specification sheets detailing KPSI, materials, weight per square meter, pile height, and recommended applications.

Knot Density (KPSI) and Quality Tiers

KPSI (knots per square inch) stands as one of the most critical quality indicators for hand knotted carpets. In practical application:

Lower KPSI (Commercial Grade)

- Approximate range: coarser construction with fewer knots

- Bold, graphic patterns with strong visual impact

- Suitable for high-traffic hospitality environments, commercial spaces, or price-conscious premium collections

Medium KPSI (Premium Grade)

- Balanced detail and durability

- Ideal for mid-to-high price point living rooms, bedrooms, and retail collections

High KPSI (Luxury Grade)

- Extraordinarily fine detailing, complex motifs, substantial weaving investment

- Suited for luxury residences, signature suites, and flagship retail projects

For each collection, we define a specific KPSI range and document it thoroughly in technical sheets, along with approximate weaving time—enabling you to plan timelines and price points with precision.

Wool, Silk & Blends – Material Standards We Use

We work exclusively with carefully sourced fibers that balance aesthetics, performance, and value:

100% Wool Hand Knotted Carpets

- Outstanding resilience, natural warmth, and inherent stain resistance

- Well-suited for living rooms, hospitality corridors, and diverse retail projects

Wool–Silk and Bamboo Silk Blends

- Wool provides structural integrity and durability; silk or bamboo silk delivers luminous sheen and visual highlights

- Creates a luxurious aesthetic ideal for feature spaces and discerning clientele

Other Fiber Options (on request)

- Cotton foundations, mixed fiber warps, or alternative materials can be specified based on your market’s technical requirements and price parameters

Every material selection can be precisely calibrated to meet specific buyer requirements—whether your focus is sustainability credentials, tactile experience, or target retail price brackets.

Pile Height, Weight per Square Meter & Construction Details

We define and document key structural parameters for each hand knotted line:

- Pile height optimized for comfort and maintenance ease

- Weight per square meter documented for logistics planning, shipping calculations, and handling protocols

- Warp and weft material composition ensuring structural stability and longevity

- Back construction details supporting authenticity verification (visible knots, no latex backing, etc.)

These specifications are provided in detailed product sheets, streamlining discussions with your own buyers, commercial clients, or regulatory authorities.

Durability, Bond Strength & Wear Performance

For commercial and hospitality buyers, durability is non-negotiable. Our hand knotted carpets are engineered to meet or exceed key performance expectations:

- Strong knot binding and pile retention under consistent foot traffic

- Colorfastness resistance against light exposure and wet cleaning (subject to dye system and cleaning protocols)

- Structural stability minimizing distortion and edge curling when properly installed

Where required, we coordinate third-party testing aligned with relevant standards (including flammability, colorfastness, or wear performance) for your target market, providing test reports as part of your comprehensive technical documentation package.

Custom Hand Knotted Carpets – Design & Development

Hand knotted carpets offer unparalleled flexibility for customization. We collaborate intimately with your design or procurement team to transform concepts into export-ready products.

Custom Sizes, Shapes & Room Layouts

We deliver:

- Standard sizes (runners, area rugs, oversized formats) for export-optimized assortments

- Custom dimensions for specific projects (lobbies, corridors, suites, villas)

- Special shapes—rounds, ovals, curves—for distinctive interior concepts

Our team works from room layouts, CAD drawings, or conceptual sketches to determine optimal sizes and proportions for each unique space.

Color Matching, Patterns & Design Libraries

For global buyers, color accuracy and repeatability are paramount. We facilitate:

- Color matching using Pantone, NCS references, or physical swatches

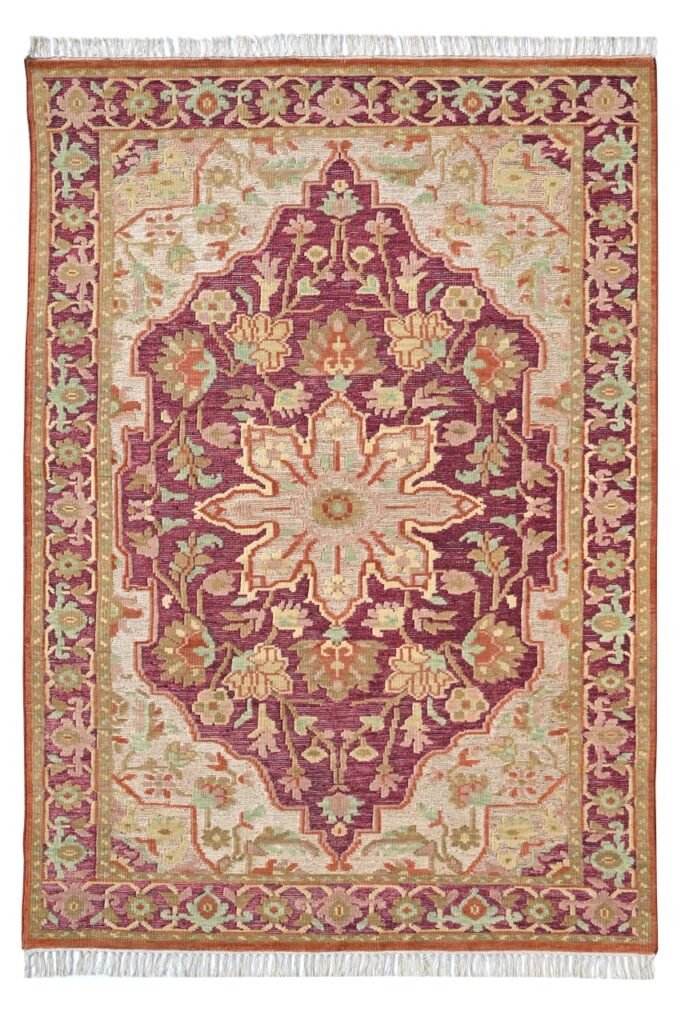

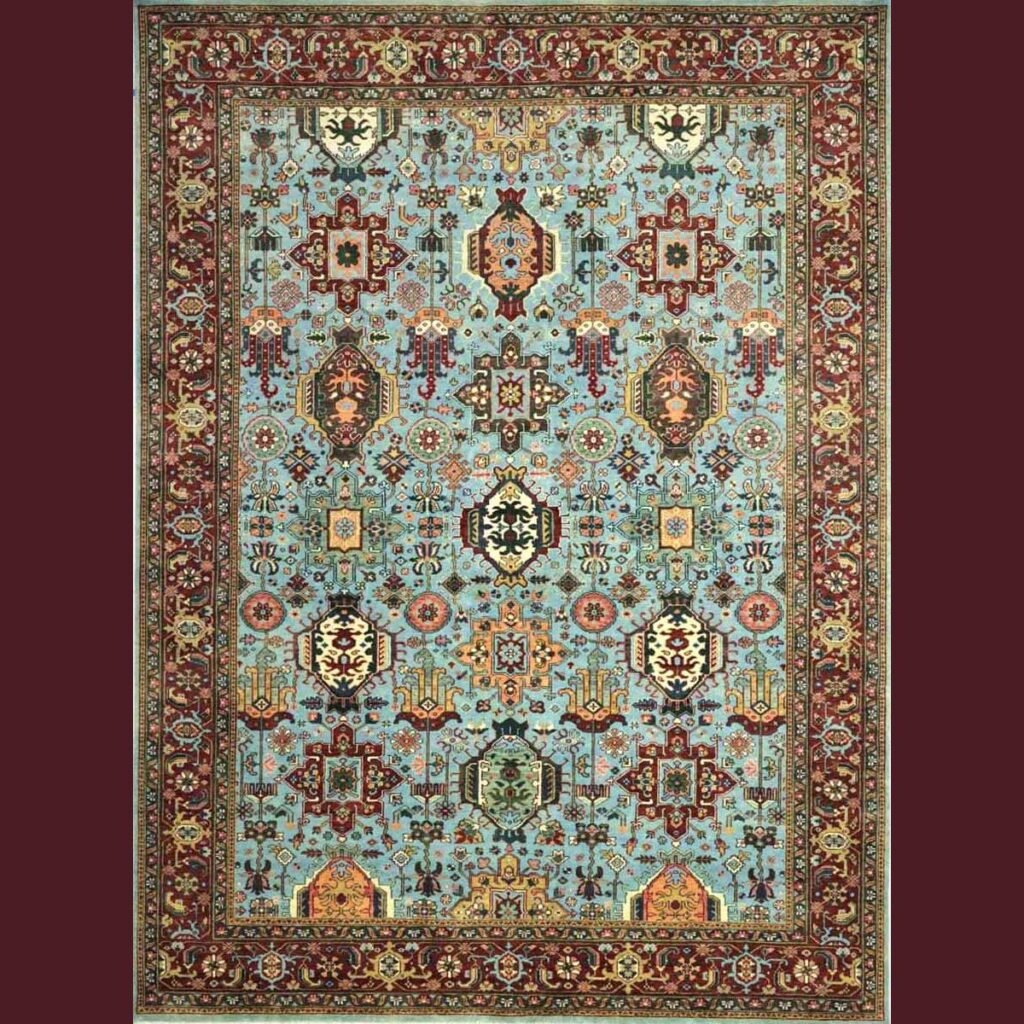

- Access to extensive pattern libraries—geometric, contemporary, traditional, transitional, Oriental-inspired, and beyond

- Recoloring capabilities for existing designs to suit specific markets (cooler palettes for European sensibilities, warmer tones for Middle Eastern preferences)

We develop design CADs for your approval before weaving commences—minimizing risk and ensuring complete alignment with your brand vision.

Custom Projects for Interior Designers & Hospitality Buyers

We’re fully equipped to manage:

- Single-project custom runs for villas, luxury homes, or flagship hospitality installations

- Multi-property rollouts for hotel chains requiring standardized or regionally adapted design guidelines

- Corporate and institutional projects where branding, color consistency, and compliance must align perfectly

For each project, we clearly define KPSI, fiber composition, expected lifespan, and maintenance recommendations—ensuring your client understands both design excellence and performance reliability.

Sample Development, Approvals & Prototyping

To eliminate uncertainty:

- We create lab-dyed yarns for color approval before full production

- Strike-off samples or partial panels are produced for critical large-scale projects

- Once samples receive approval, full production begins with transparent timelines and rigorous batch control

Typical weaving time for hand knotted carpets correlates directly with KPSI, size, and design complexity. A single rug may require anywhere from several weeks to several months; larger programs are scheduled strategically to balance production capacity with delivery commitments.

Export Markets & Compliance by Region

We don’t simply manufacture—we help you navigate import procedures, customs processes, and compliance landscapes.

Hand Knotted Carpet Export to USA (HS Code, CPSC, Flammability)

For the USA market, hand knotted carpets typically fall under HS code 5701, covering knotted carpets and textile floor coverings. We support you with:

- Precise classification under HS 5701 for customs documentation

- Technical data required for CPSC-related and flammability-related compliance where applicable

- Accurate labeling (fiber content, country of origin) conforming to US regulations

- Seamless coordination with your freight forwarder or nominated consolidator

- HS Code 5701 Reference (U.S. ITC)

https://hts.usitc.gov/?query=5701

Exporting to Europe & Germany (REACH, EU Standards)

For EU and German markets:

- We facilitate alignment with REACH-related expectations for dyes and chemical substances used in production

- We supply documentation on fiber content and dye systems where required

- Technical supporting data can be shared for testing and certification processes should you pursue local marks or labels

Exporting to UK Post-Brexit

For the United Kingdom:

- We maintain HS 5701 classification and comprehensive associated documentation

- Provide UK-specific commercial invoices, packing lists, and certificates of origin as needed

- Support your broker or customs agent with any additional technical details required for smooth clearance

Exporting to UAE & Saudi Arabia (Gulf Market Requirements)

For Gulf markets:

- Support with HS 5701 classification and Arabic labeling requirements (where requested)

- Robust packing engineered to withstand extended sea routes and elevated temperature variations

- Coordination with your logistics partners for consolidation optimization and container efficiency

- GoodWeave Certification (Ethical Rugs)

https://goodweave.org/

Exporting to Australia & Oceania

For Australian and Oceanic markets:

- Assistance with HS 5701 documentation for customs clearance

- Protective packing designed to minimize damage and moisture exposure during transit

- Clear, comprehensive documentation and labeling to facilitate import inspections

Documentation, HS Codes & Customs Clearance Support

We routinely provide:

- Commercial invoice

- Detailed packing list (specifying sizes, weights, and packaging)

- Certificate of origin (from Chamber of Commerce)

- HS code declaration (5701, with appropriate sub-heading per product)

- Bill of lading / airway bill (from shipping partner)

- Any mutually agreed test reports or certifications

- Additional documents requested by your customs broker (subject to agreement)

Quality Assurance, Testing & Certifications

Trust is built on unwavering quality and transparent testing protocols.

In-House Quality Control Process (From Yarn to Final Inspection)

We follow a rigorous, structured QC system:

- Yarn inspection for count accuracy, strength, and consistency

- In-process checks on knot uniformity, design fidelity, and loom tension

- Post-weaving inspection of dimensions, shape, and pattern alignment

- Final quality control after washing and finishing, approving each carpet before packing

Third-Party Testing & Lab Reports (Colorfastness, Flammability, etc.)

For buyers requiring documented performance verification:

- We coordinate independent laboratory testing for parameters including:

- Colorfastness to light and rubbing

- Dimensional stability / shrinkage

- Flammability behavior, aligned with requested standards

- Test reports are provided as part of your technical and compliance documentation file

Certifications & Standards (Examples & Alignment)

Depending on buyer requirements and project scale, we facilitate alignment with or support external certification to standards such as:

- Quality management systems (ISO-based frameworks at partner facilities)

- Textile and chemical safety certifications where applicable

- Social and ethical compliance audits as agreed with buyers

Details are discussed and clearly defined per program, ensuring expectations are established from the outset.

Authenticity Verification & Certificates of Origin

To help you and your customers verify authenticity:

- Clear back structure displaying visible knots without synthetic backing

- Documentation explicitly stating “Hand Knotted” and “Made in India”

- Certificates of origin and supporting invoices that align precisely with your customs entries

Bulk Orders, MOQ, Pricing & Lead Times

Importers and project buyers require predictability—not unwelcome surprises.

Minimum Order Quantities for Hand Knotted Carpets

As a factory-direct exporter, we structure MOQs to be commercially viable:

- Practical MOQs for trial orders—smaller mixed-design shipments for new buyers testing new markets

- Container-optimized MOQs for full, consistent programs with economies of scale

- Custom project MOQs defined based on size, KPSI, and design complexity

Exact MOQs are established project-by-project, allowing us to balance weaving capacity, cost efficiency, and your market’s demand profile.

Wholesale Pricing Structure & Volume Discount Tiers

We operate on a transparent wholesale model for hand knotted rugs:

- Base pricing determined by KPSI, material composition (wool vs wool–silk), size, and design complexity

- Volume-based pricing for larger orders or multi-season programs

- Project-based quotations for hospitality and corporate installations

We provide per-square-meter or per-piece pricing, enabling straightforward landed cost calculations and retail margin planning.

FOB/FCA Pricing, Payment Terms & Trade Finance Options

We typically quote:

- FOB Indian ports (Mundra, Nhava Sheva) or FCA arrangements if required

- Payment terms agreed based on order size, buyer profile, and relationship history (for example: advance + balance on documents, LC for larger or institutional orders, etc.)

All terms are clearly documented in proforma invoices to ensure complete alignment before production begins.

Production Lead Time by KPSI & Order Size

Weaving time for hand knotted carpets correlates directly with:

- Knot density (KPSI)

- Design complexity

- Size and total order volume

As a general framework:

- Lower KPSI, smaller orders: considerably shorter lead times

- High KPSI, large-format or multi-piece luxury projects: extended lead times, planned collaboratively with you

We share indicative lead time ranges during the quotation stage and refine them once designs and quantities are finalized.

Shipping, Insurance & Delivery Timeline Estimates

We support you with:

- Coordination with nominated freight forwarders or our recommended logistics partners

- Guidance on optimal packing methods (bales, rolls, or cartons) for your specific route and market

- Insurance options (through your provider or via arranged coverage on request)

- Clear ETD and ETA windows, enabling you to plan downstream distribution or installation schedules with confidence

Sustainability & Ethical Hand Knotted Carpet Production

Sustainability and ethical practices are increasingly central to informed buyer decisions.

Natural Dyes, Eco-Friendly Processes & Water Conservation

Where collections are specified with environmental focus, we can:

- Prioritize natural or low-impact dye systems where practical

- Employ processes designed to optimize water usage in washing and finishing stages

- Collaborate with you on marketing claims that are both compelling and authentic

Ethical Sourcing, Fair Wages & Community Impact

Hand knotted carpets sustain artisan communities. We partner with manufacturing facilities that:

- Provide equitable compensation structures for weavers

- Preserve traditional weaving skills in India’s historic carpet-making regions

- Create long-term, stable employment opportunities for artisan communities

Sustainable Packaging & Carbon Footprint Reduction

We facilitate:

- Reduced-plastic or recyclable packaging options where logistics permit

- Strategic load planning that maximizes container utilization, reducing emissions per square meter transported

These initiatives integrate seamlessly into your sustainability narrative for your own customers.

Case Studies & Buyer Testimonials

Hospitality Project – Hand Knotted Carpets for Hotel Lobby & Suites

A hospitality buyer commissioning hand knotted carpets for a flagship property requires durability, design coherence, and punctual delivery. We collaborate with them to:

- Define appropriate KPSI and fiber composition for lobby and suite traffic patterns

- Develop harmonious color stories across multiple property areas

- Schedule weaving and dispatch in phases aligned with construction and fit-out timelines

Retail Importer – Building a Profitable Hand Knotted Collection

For a multi-location retailer:

- We help design a curated assortment spanning commercial, premium, and luxury KPSI tiers

- Provide comprehensive product data, professional photography, and care instructions ready for digital and in-store deployment

- Align price points with target retail margins and typical market price bands

Interior Designer – Bespoke Hand Knotted Rug for Luxury Residence

For a distinguished interior designer:

- We translate their creative vision into a hand knotted rug with custom colors, dimensions, and KPSI

- Provide samples and CADs before weaving begins

- Deliver a centerpiece that becomes a signature element in their project portfolio

Wholesale Distributor – Scaling Regional Hand Knotted Rug Supply

For distributors:

- We support multi-SKU programs across sizes, colors, and styles

- Ensure repeatability so key SKUs can be confidently reordered

- Offer flexible packing and shipment planning for regional warehousing needs

How to Work with Scalane International (Step-by-Step)

Step 1 – Share Your Project or Buying Requirements

Send us a brief detailing:

- Target market(s) and buyer segment (retail, hospitality, online, etc.)

- Approximate budget or target retail price band

- Preferred styles, colors, and sizes

- Any specific technical or certification requirements

Step 2 – Get Samples, Designs & Technical Specs

We respond with:

- Curated design options (existing or custom) with comprehensive specifications

- Technical sheets outlining KPSI, materials, weight, and recommended applications

- Sample plan—yarns, strike-offs, or existing samples, depending on project scale

Step 3 – Finalize Order, Payment Terms & Production Timeline

Once designs and specifications are approved:

- We finalize quantities, sizes, and assortments

- Agree on pricing (FOB/FCA) and payment terms

- Confirm production lead time and shipping plan

Step 4 – Quality Checks, Packing & Dispatch

Throughout production:

- QC checks are conducted at critical stages

- Completed carpets are inspected, packed, and labeled

- Shipment is booked, and you receive regular ETD/ETA updates

Step 5 – Post-Delivery Support & Reorder Process

After delivery:

- We provide ongoing support for installation, maintenance, and customer inquiries

- Successful SKUs and designs can be reordered or extended into new colorways or sizes

- For project clients, we support future phases or new property pipelines

FAQs on Hand Knotted Carpet Export & Import

How do I verify that your hand knotted carpets are authentic?

Authentic hand knotted carpets display individual knots on the back, not a latex or synthetic backing layer. We provide clear photographic documentation of the back structure, detailed specifications (including KPSI and material breakdown), and documentation confirming that our carpets are hand knotted in India. Certificates of origin and, where agreed, inspection reports further support authenticity verification.

What is the difference between hand knotted, hand tufted and machine made carpets?

Hand knotted carpets are created by individually tying knots on a loom, offering superior detail, durability, and lasting value. Hand tufted carpets use a tufting gun to punch yarn through a backing, with a secondary backing added—faster and more economical. Machine made carpets are produced on power looms for speed and volume, with diminished artisanal character. For your assortment, hand knotted represents the premium and luxury segment.

What knot density (KPSI) do you offer for hand knotted carpets?

We work across multiple KPSI bands—from practical commercial and premium grades to fine luxury grades. The exact KPSI depends on the collection and price point you’re targeting. During development, we specify the KPSI range for each design, enabling accurate positioning within your portfolio.

How long does it take to produce a bulk order of hand knotted carpets?

Lead times correlate with KPSI, design complexity, and total volume. Lower KPSI and smaller volumes can be completed relatively quickly, while high KPSI, large-format, or multi-piece luxury projects naturally require extended timeframes. We provide clear estimated timelines at the quotation stage and refine them once the final order is confirmed.

What is the minimum order quantity (MOQ) for hand knotted carpets?

MOQ depends on construction, KPSI, and whether the order is for stock collection or custom projects. We offer practical trial MOQs for new customers and more optimized MOQs for full programs or container loads. During discussions, we clarify MOQs for each design and size combination, enabling confident order planning.

Which countries do you export hand knotted carpets to?

We export from India to USA, UK, Europe (including Germany), Middle East (UAE, Saudi Arabia and others), Australia, and several emerging markets. If your country isn’t listed, we can typically explore shipment options and compliance requirements together.

What certifications and test reports can you provide for hand knotted carpets?

Depending on your project and market requirements, we coordinate third-party testing for parameters such as colorfastness, flammability behavior, and other performance metrics. We also provide certificates of origin and comprehensive technical data sheets. Additional audits or certifications can be discussed project-by-project.

How are hand knotted carpets packed and shipped for export?

Carpets are typically rolled or folded (depending on size and specification), wrapped securely, and packed into bales or cartons. We plan packing to protect carpets from moisture, abrasion, and handling during transit. Shipments move under HS code 5701 with complete commercial invoices, packing lists, and other required documents, either by sea (FCL/LCL) or air for time-sensitive orders.

What are your payment terms for international buyers?

Payment terms are defined based on order value, buyer profile, and relationship history. Common structures include partial advance with balance against documents, or letters of credit for larger institutional orders. Our focus is creating a structure that appropriately balances risk and cash flow for both parties.

Can you customize colors, sizes and designs for hospitality or interior design projects?

Absolutely. Customization is a core strength. We collaborate closely with your design team on colors, patterns, sizes, and KPSI. For hospitality and interior design projects, we align designs with brand standards, durability requirements, and maintenance considerations.

Do you offer samples before confirming a bulk hand knotted carpet order?

We provide yarn samples, design CADs, and, for larger or strategic projects, physical strike-off samples. Sampling plans are tailored to the scale and timeline of your specific project.

How long do hand knotted carpets typically last in commercial or high-traffic spaces?

With appropriate specifications (correct KPSI and fiber composition for the application) and proper maintenance, hand knotted carpets can deliver many years of reliable service, often outlasting other constructions in comparable conditions. We advise on suitable quality levels for each project type, helping you balance initial investment with lifespan and overall return on investment.

Final Call to Action – Start Your Hand Knotted Carpet Project

If you’re seeking a reliable, export-ready partner for hand knotted carpets from India—with transparent technical data, HS code 5701 classification support, comprehensive export documentation, and project-focused customization—Scalane International is ready to collaborate with you.

- Factory-direct sourcing from India’s premier carpet-making clusters

- Export processes designed specifically for global B2B buyers

- Custom designs, clear KPSI and material specifications, and meticulous QC at every stage

REQUEST CUSTOM QUOTE : +91 9428805354 (whatsapp)

EMAIL : exports@scalaneinternational.com