This 2025 guide explains porcelain vs ceramic tiles with complete technical specifications, export requirements, ISO standards, and buyer-focused comparisons.

Table of Contents

- Introduction

- Porcelain vs Ceramic – Technical Specifications (2025)

- Composition

- Water Absorption (ISO 10545-3)

- Hardness (MOHS)

- PEI Rating

- Slip Resistance (DIN / AS4586)

- Thickness Options

- Finishes

- Rectification Accuracy

- Warpage Limits

- Manufacturing Difference (Pressing, Firing, Raw Materials)

- Export Requirements (USA, UAE, UK, Australia)

- Size Demand by Country

- Technical QC Problems Buyers Face (& How to Solve Them)

- Mandatory Testing & Certifications

- Packing, Pallets & Container Loading

- Competitor Comparison: India vs China vs Spain vs Italy vs Turkey

- Buyer’s Checklist (2025)

- FAQ

- Conclusion

1. Introduction

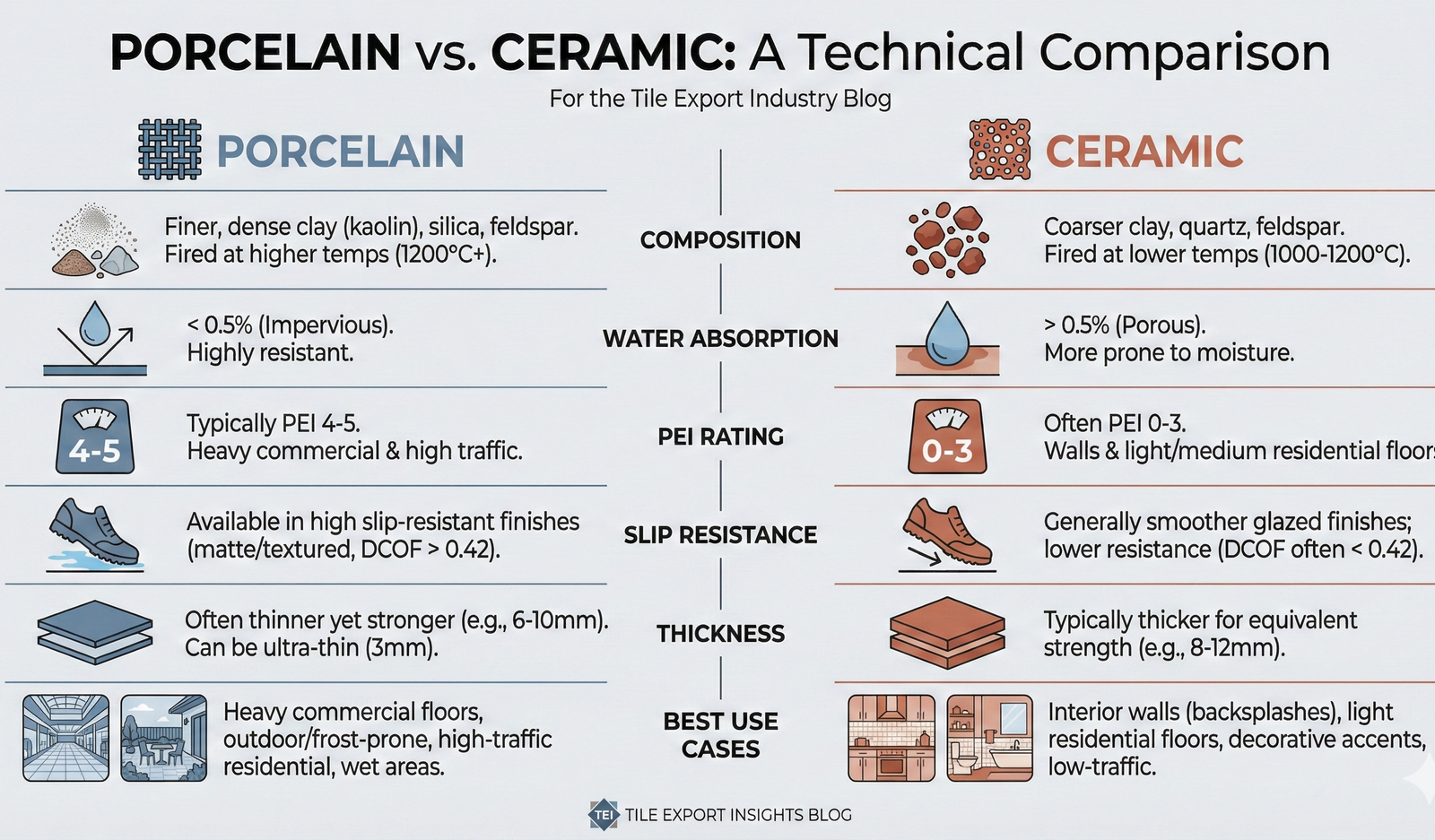

Choosing between porcelain vs ceramic tiles is one of the most common decision points for buyers, importers, wholesalers, and project developers worldwide. While both products belong to the ceramic family, their technical performance, durability, water absorption, PEI, slip resistance, and export suitability vary significantly. Porcelain vs ceramic tiles differ mainly in water absorption, hardness, PEI rating, slip resistance, and long-term durability in export markets.

In 2025, global markets—especially the USA, UAE, UK, and Australia—have shifted toward highly technical porcelain tiles that comply with strict ISO, ASTM, DIN, and AS4586 standards.

This guide gives you a complete technical comparison of porcelain and ceramic tiles, plus an export-focused buyer manual covering QC, loading, palletization, and testing.

2. Porcelain vs Ceramic Tiles – Technical Specifications (2025)

2.1 Composition

Porcelain Tiles

- Made from refined kaolin clay, feldspar, and silica

- High density body, minimal porosity

- Fully vitrified

- Fired at 1200–1300°C

- Pressing pressure: ≥450 kg/cm²

Ceramic Tiles

- Made from red/white natural clay mix

- Higher porosity

- Fired at 1000–1150°C

- Less dense and lighter body

Conclusion: Porcelain has a much stronger, vitrified structure; ceramic is more economical and suited for indoor use.

2.2 Water Absorption (ISO 10545-3)

Porcelain: ≤0.5%

Ceramic: >3%

This is the biggest differentiator. Water absorption directly affects durability, stain resistance, and frost resistance, especially for export.

2.3 Hardness (MOHS Hardness Scale)

- Porcelain: MOHS 7–8

- Ceramic: MOHS 5–6

Higher MOHS means porcelain withstands abrasion and heavy traffic.

2.4 PEI Rating (Abrasion Resistance)

- Porcelain: PEI 4–5 → Suitable for commercial & heavy residential

- Ceramic: PEI 2–4 → Suitable for low or moderate residential

2.5 Slip Resistance (DIN / AS4586)

Porcelain offers a wide slip resistance range:

- R9–R13 (DIN standard)

- P2–P5 (AS4586 standard)

Ceramic mostly remains at R9–R10, suitable only for indoor spaces.

Outdoor / wet area requirement countries:

- Australia: P3–P5

- UAE: R11+

- UK: R10+

- USA: COF-based (≥0.42 DCOF for wet floors)

2.6 Thickness Options

Porcelain: 6mm, 8mm, 9.5mm, 10mm, 12mm, 20mm outdoor pavers

Ceramic: 6mm–10mm

2.7 Finishes Available (2025)

Porcelain

- Matte

- Glossy

- Polished

- Carving

- Lappato

- Soft-grip

- Sugar finish

- Outdoor texture (R12/R13)

- Stone/wood replicas via digital printing

Ceramic

- Matte

- Glossy

- Satin

- Limited textures

2.8 Rectification (Cutting Accuracy)

Porcelain: ≤0.3mm (high precision, tight joints)

Ceramic: Higher variance, limited rectified options

2.9 Warpage / Flatness (ISO 10545-2)

Maximum tolerance depends on size:

- Porcelain: ≤±0.5% or ≤1.5mm

- Ceramic: More prone to bowing and deformation

3. Porcelain vs Ceramic Tiles – Technical Summary (2025)

Porcelain Manufacturing

- High-tonnage pressing

- Higher firing temperature

- Lower porosity body

- Advanced digital printing ensures V2–V4 shade variation

Ceramic Manufacturing

- Lower firing temperature

- More porous body = less strength

- Shade variation mostly V1–V3

Porcelain technology has matured with high-definition digital inkjet, carving surfaces, and precise polishing lines. Importers compare porcelain vs ceramic tiles to understand which performs better in ISO testing, outdoor applications, and high-traffic flooring.

4. Export Requirements (USA, UAE, UK, Australia)

USA

- High demand for porcelain

- Preferred sizes: 600×600, 600×1200, 800×800, 1200×1200

- Requires ISO + ANSI + DCOF ≥0.42

UAE / GCC

- Polished porcelain

- Marble looks

- Slip rating R11+ for commercial

- Demand for large slabs 240×120cm

UK

- Frost-resistant porcelain

- Slip rating R10–R12

- Sizes: 600×600, 600×1200, wood planks

Australia

- Strict AS4586 slip testing

- Outdoor R12+ & P4–P5 mandatory

- Popular sizes: 45×90, 30×120, 60×60, 20mm pavers

5. Size Demand

| Country | Popular Sizes |

|---|---|

| USA | 600×600, 600×1200, 300×600, 800×800, 1200×600 |

| UAE | 60×60, 80×80, 120×60, 240×120 |

| UK | 60×60, 60×120, 20×120 |

| Australia | 60×60, 45×90, 30×120, 20mm outdoor |

Ceramic demand is shrinking globally for floors; porcelain is becoming “default” for high-spec projects.

6. Technical QC Problems Buyers Face (& Solutions)

6.1 Warpage/Bowing

Problem: Tiles bend > ISO limits

Solution:

- Ensure <±1.5mm warpage for large formats

- Check calibration after kiln exit

- Request ISO 10545-2 flatness test report

6.2 Shade Variation / ΔE*

Problem: Shade mismatch within the same batch

Solution:

- Strict ink calibration

- Use digital masters with controlled firing curves

- Always test first firing of batch

6.3 Rectification Issues

Problem: Incorrect edge cutting causes uneven joints

Solution:

- Ask for rectification accuracy ≤0.3mm

- Check edge calibration report

6.4 Slip Resistance Mismatch

Problem: Buyer orders R12 but receives R10

Solution:

- Always demand slip test report (DIN/AS4586)

- Random third-party test from exporter

6.5 Water Absorption Not Matching “Porcelain”

Problem: WA >0.5% causes export rejection

Solution:

- ISO 10545-3 test for each batch

- Maintain controlled pressing & firing

6.6 Packaging Breakage

Problem: Damage during ocean transit

Solution:

- Edge guards, corner protection

- Carton weight <30kg for manual handling

- Shrink wrap + moisture barrier

7. Mandatory Testing & Certifications (2025)

Required Tests

- ISO 10545-2 (Dimensions, flatness)

- ISO 10545-3 (Water absorption)

- ISO 10545-4 (Breaking strength)

- ISO 10545-7 (Abrasion – PEI)

- ISO 10545-12 (Frost resistance)

- ISO 10545-13 (Chemical resistance)

- AS4586 slip resistance

- DCOF (USA wet surfaces standard)

Documents Buyers Request

- Batch QC certificate

- Slip test report

- MOHS hardness test

- MSDS / silica content

- Packing list with pallet details

- Heat-treatment certificate (ISPM-15)

For overseas buyers, choosing porcelain vs ceramic tiles depends on technical specifications, QC stability, and compliance with international standards.

8. Packing, Palletization & Container Loading

8.1 Pallet Requirements

- ISPM-15 certified wooden pallets

- Slip sheets

- Moisture protection

- Shrink wrap

- Carton ≤30kg

8.2 Container Loading (Porcelain 600×600mm)

- 20ft: 800–950 sqm

- 40ft HC: 1600–1900 sqm

- Max weight: 27 tons

9. Competitor Comparison: India vs China vs Spain vs Italy vs Turkey

India

- Excellent digital printing

- Strong porcelain lines

- Slip rating R10–R12 achievable

- Very good value

- Large format improving (slabs, 120×120, 800×1600)

China

- Broad quality range

- Rapid design replication

- QC inconsistency risk in bulk

- Competitive for basic porcelain

Spain

- Highly refined finish

- Excellent consistency

- Best calibrated rectified edges

- Strong eco-standards & lifecycle testing

Italy

- Benchmark for luxury porcelain

- Industry-leading designs and innovation

- Ultra-matt, carving, lappato finishes

- Highest technical stability

Turkey

- Strong stone-look tiles

- Good technical consistency

- Competitive mid-range positioning

10. Buyer’s Technical Checklist (2025)

- Confirm ISO 10545-3 WA ≤0.5% for porcelain

- Check PEI rating 4 or 5 for commercial

- Demand slip resistance R11/P4+ for outdoor

- Check rectification accuracy ≤0.3mm

- Verify thickness tolerance

- Ask for flatness test report

- Confirm shade variation V2–V4 (for stone/wood looks)

- Ask for ISPM-15 pallet certification

- Inspect packaging method

- Review past QC complaints

11. FAQ

Q1. What is the main difference between porcelain and ceramic tiles?

Porcelain has ≤0.5% water absorption and higher density; ceramic has >3% and is lighter.

Q2. Which tile is better for high-traffic export projects?

Porcelain (PEI 4–5, MOHS 7–8).

Q3. Which countries require the highest slip ratings?

Australia (P3–P5), UAE (R11+), UK (R10–R12).

Q4. How do I check if a tile meets ISO standards?

Request ISO test reports (10545 series) and verify batch results.

Q5. Can ceramic tiles be used outdoors?

Not recommended due to high water absorption and low frost resistance.

12. Conclusion

If you want porcelain or ceramic tiles that meet strict 2025 export standards, ensure your supplier provides:

✔ ISO-certified production

✔ Accurate rectification

✔ Proper slip testing (DIN, AS4586, DCOF)

✔ Strong packing for long-distance shipments

To receive:

- Full technical catalogue

- Export packing details

- Sample box for your market

Contact us to get complete technical specs, test reports, and shipment assistance.

Pingback: Tiles Export to Jamaica (2026 Guide): Import Rules & Demand

Comments are closed.