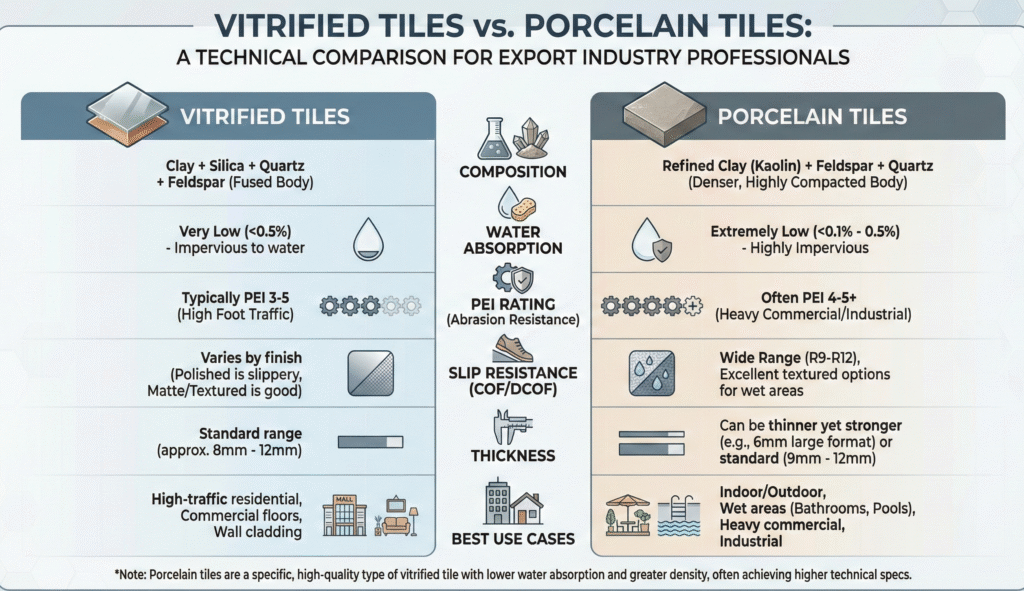

For a tile importer or distributor, “vitrified tiles vs porcelain tiles” is not just a design choice. It affects water absorption, slip resistance, warpage, container loading, QC claims, and ultimately reputation in the market.

This in-depth 2025 guide from Scalane International is written for tile importers, wholesalers, architects and project buyers who want a technical but practical comparison of vitrified tiles vs porcelain tiles – plus a clear export roadmap. This guide compares vitrified tiles vs porcelain tiles to help importers understand technical differences.

Table of Contents

- What Are Vitrified Tiles vs Porcelain Tiles? (Technical Definitions)

- Technical Comparison: Composition, Manufacturing, Water Absorption, PEI, Slip Ratings, Hardness

- Thickness, Rectification, Warpage & Shade Variation (How to Avoid Complaints)

- Performance by Application: Indoor, Outdoor, Commercial & High-Traffic

- Market-Wise Demand: USA, UAE & Middle East, Europe, Australia, UK & Others

- Packing, Palletization & Container Loading for Tile Exports

- Common Problems Importers Face (Warpage, Shade, Flatness, Breakage) & Solutions

- Testing & Documentation Checklist (ISO, DIN, AS 4586, CE, ANSI)

- India vs China vs Spain vs Italy vs Turkey – Competitor Technical Benchmark

- FOB Export Structures for Porcelain & Vitrified Tiles

- FAQ: Vitrified Tiles vs Porcelain Tiles – Technical Buyer Questions

- How Scalane International De-Risks Tile Imports

1. What Are Vitrified Tiles vs Porcelain Tiles? (Technical Definitions)

Vitrified Tiles – Overview

- Base: Clay mixed with other minerals, fired to achieve a vitreous, dense body.

- Water absorption: Typically 0.5–1.0%, classified as vitreous.

- Use case: Popular as ceramic floor tiles in residential and light commercial projects.

- Look & finishes: Available in matte finish tiles, glossy, lappato, carving, sugar, soft-grip, etc.

- Export positioning: Ideal for buyers seeking a balance of cost, durability, and aesthetics.

Porcelain Tiles – Overview

- Base: More refined kaolin clay, feldspar, quartz and carefully controlled mineral mix.

- Water absorption: ≤0.5%, classified as impervious porcelain tiles.

- Use case: Outdoor porcelain tiles, freeze-thaw resistant tiles, heavy-traffic commercial floor tiles.

- Strength: Higher density and MOHS hardness 7–8, excellent scratch resistance.

- Export positioning: Premium product for high-performance, low water absorption tiles in demanding climates.

Where Ceramic Tiles Fit In

- Standard ceramic tiles:

- Water absorption 3–7% (semi-vitreous) or >7% (non-vitreous wall tiles).

- Best used as indoor wall tiles, low-traffic floors.

- For export buyers: Ceramic floor tiles are still relevant but porcelain and vitrified tiles dominate where technical performance and long-term durability matter.

2. Technical Comparison: Composition, Manufacturing, Water Absorption, PEI, Slip Ratings, Hardness

2.1 Composition & Manufacturing Process

Common manufacturing stages for vitrified and porcelain tiles:

- Raw material preparation (ball mill grinding)

- Spray drying to obtain fine, uniform powder

- Hydraulic pressing to form tiles (higher pressure for porcelain tiles)

- Drying to remove moisture

- Glazing (matte, glossy, lappato, satin, carving, sugar, anti-slip coatings)

- High-temperature roller kiln firing

- Porcelain tiles: ~1200°C+

- Vitrified tiles: ~1030°C

- Standard ceramic tiles: ~1050–1100°C

- Sorting, grading, quality control, packaging and palletization

Key takeaway for buyers:

Porcelain tiles use more refined raw materials and higher firing temperatures, giving higher density, lower water absorption and better technical strength compared to standard vitrified or ceramic floor tiles. When evaluating vitrified tiles vs porcelain tiles, water absorption and slip ratings are the most critical parameters

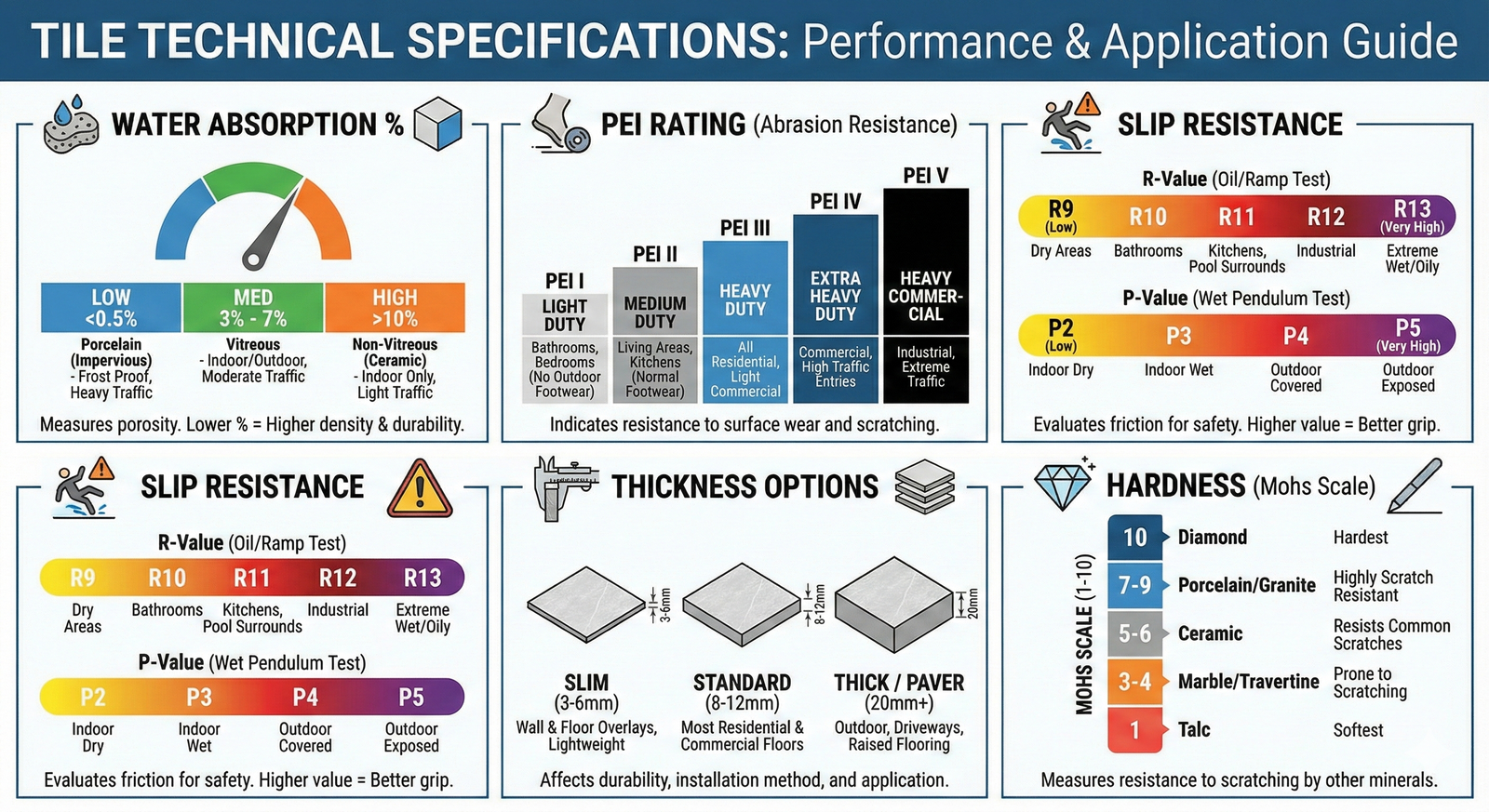

2.2 Water Absorption, PEI Rating, MOHS Hardness & Slip Resistance

Technical Comparison Table

| Parameter | Porcelain Tiles | Vitrified Tiles | Ceramic Tiles |

|---|---|---|---|

| Water Absorption (ISO 10545-3) | ≤ 0.5% (impervious) | 0.5–1.0% (vitreous) | 3–7% (semi-vitreous), >7% (wall) |

| Classification | BIa GL (porcelain) | Vitreous floor tiles | Semi-/non-vitreous |

| PEI (Glazed) | Typically PEI 3–5 | PEI 3–4 (depending on glaze) | PEI 2–3 mostly |

| MOHS Hardness | 7–8 (very scratch-resistant) | ~6–7 | 5–6 |

| Typical Slip Ratings | R9–R13 / P1–P5 (finish dependent) | R9–R11 / P1–P4 | R9–R10 (limited higher ratings) |

| Freeze-Thaw Resistance | Excellent (suitable for outdoors) | Good in many climates, check data | Poor to moderate |

PEI Rating (Porcelain Enamel Institute)

- PEI 0: Walls only, no foot traffic.

- PEI 1–2: Very light traffic (guest bathrooms).

- PEI 3: Moderate traffic (kitchens, living rooms).

- PEI 4: Heavy residential, light commercial.

- PEI 5: Very heavy commercial traffic (airports, malls, hospitals).

For export buyers, focus on PEI 4–5 tiles for commercial floor tiles and high-traffic projects.

MOHS Hardness

- Porcelain tiles at 7–8 MOHS resist scratching from sand and grit better than most natural stones.

- This is critical for outdoor porcelain tiles, large format tiles in lobbies, and commercial floor tiles where rolling loads and frequent cleaning are expected.

2.3 Slip Resistance – DIN 51130, AS 4586, DIN 51097

DIN 51130 (R-Ratings, shod feet)

- R9: 6–10° – dry indoor spaces (low slip risk)

- R10: 10–19° – kitchens, entrances, occasional wet areas

- R11: 19–27° – frequently wet, commercial kitchens, laundries

- R12: 27–35° – food industries, pool surrounds

- R13: >35° – industrial, very high contamination risk

Architects often evaluate vitrified tiles vs porcelain tiles based on slip resistance ratings like R10, R11 or R12.

AS 4586 (Pendulum test, P-Ratings)

- P0–P2: Low slip resistance (not ideal for wet floors)

- P3–P4: Moderate to high slip resistance

- P5: Very high slip resistance (recommended for outdoor wet areas)

DIN 51097 (Barefoot areas)

- A: Light slip risk (dry/barefoot zones)

- B: Pools, domestic showers

- C: Commercial pools, spa & gym showers, jacuzzis

For R11 slip resistant tiles or R13 non-slip tile for pools, porcelain tiles with textured, carving, sugar or soft-grip finishes are usually the best fit.

3. Thickness, Rectification, Warpage & Shade Variation (How to Avoid Complaints)

3.1 Tile Thickness Options

- Ultra-thin tiles (3–6 mm): Wall cladding, low-load areas.

- Standard wall tiles (6–8 mm): Kitchens, bathrooms.

- Residential floors (8–10 mm): Bedrooms, low-traffic floors.

- General floors (10–12 mm): Living rooms, standard commercial.

- Heavy-traffic floors (15–20 mm): Malls, stations, outdoor patios.

- Outdoor/driveway tiles (20+ mm): High load capacity, weather resistance.

For exporters and buyers, thickness directly affects:

- Breaking strength & modulus of rupture

- Weight per box and per container

- Container capacity optimisation

3.2 Rectification & Dimensional Accuracy (ISO 10545-2, ANSI A137.1)

Key tolerances you should demand in a ceramic tile specification sheet or porcelain tile technical data:

- Dimensional tolerance: ±1.0% up to max ±2 mm (standard), ±2.0% (commercial).

- Straightness of sides: ±0.5–0.6% of tile size.

- Rectangularity: ±1.0% deviation from true 90°.

- Surface flatness (center curvature): ±0.5–1.5% of diagonal.

Rectified tiles (precisely cut edges) allow:

- Narrow grout joints

- High-end modern look

- Better alignment for large format tiles (600×600, 600×1200, 800×800)

But they also magnify substrate and warpage issues, so QC is critical. In most international markets, the choice between vitrified tiles vs porcelain tiles depends on climate and durability needs.

3.3 Warpage / Bowing Limits

- ISO 13006: Maximum ±0.5% of tile edge length.

- Example: For a 600 mm tile, max allowable bow is ~3 mm.

- ANSI A137.1: Similar limits, with stricter rules for large format tiles.

- For 24″ (≈610 mm) tiles, warpage tolerance can be ~0.75% (~4.5 mm), but best-in-class manufacturers stay much lower.

Buyer tip:

In specifications and pre-shipment inspection checklists for warpage-free flat tiles, insist on:

- Warpage test results as per ISO 10545-2

- On-site lippage and flatness tests during installation

- Substrate flatness within ±1/8″ in 10 feet

3.4 Shade Variation (V1–V4 Scale)

- V1 – Uniform: Almost no variation (solid colour).

- V2 – Slight: Some variation, overall consistent.

- V3 – Moderate: Noticeable variation across pieces, more “natural stone” feel.

- V4 – Substantial: Very high variation, each tile may look unique.

When marketing digital printed tiles, carving tiles, or textured floor tiles, always clearly communicate the V-rating to avoid surprises for the end customer. The biggest difference in vitrified tiles vs porcelain tiles comes from their water absorption and firing temperature.

4. Performance by Application: Indoor, Outdoor, Commercial & High-Traffic

4.1 Indoor Dry Areas

- Suitable tiles: Ceramic floor tiles, vitrified tiles, porcelain tiles.

- Water absorption: Higher absorption is acceptable for wall tiles; floors should be more controlled.

- Finish: Glossy tiles for walls, matte, satin or lappato finish tiles for floors.

4.2 Bathrooms, Kitchens & Wet Areas

- Use vitrified or porcelain tiles with:

- Water absorption <0.5–1%

- R10–R11 / P3–P4 slip resistance

- Ideal choices:

- Anti-slip tiles, textured tiles for slip resistance, soft-grip finishes.

- Avoid plain glossy tiles on wet floors (slip resistance issues with glossy tiles).

4.3 Outdoor, Freeze-Thaw & Harsh Climates

- Use porcelain tiles <0.5% water absorption only.

- Ensure freeze-thaw cycling tiles have test data.

- Prefer R11–R13 slip ratings and P4–P5 for wet outdoors.

- Large patios and alfresco areas often use 600×600 porcelain tiles or 800×800 durable large format tiles.

4.4 Commercial & High-Traffic Projects

- Airports, malls, hospitals, stations:

- Full-body porcelain tiles, double-charged tiles, or high-grade glazed porcelain.

- PEI 4–5 high-traffic commercial tiles.

- MOHS hardness ≥7, R11+ where wet conditions exist.

- Use chemical resistant tiles in kitchens, labs and heavy-duty areas.

5. Market-Wise Demand: USA, UAE & Middle East, Europe, Australia, UK & Others

5.1 USA Market

- Strong demand for porcelain tiles with <0.5% water absorption.

- Large format tiles 600×600, 600×1200, 800×800 growing rapidly.

- Preferences:

- Nature-inspired looks (wood, stone, concrete).

- Digital printed ceramic tiles wholesale for cost-sensitive segments.

- Focus on:

- Porcelain tile suppliers offering ISO 13006 compliance tiles + ANSI A137.1 USA standard tiles.

- Freeze-thaw rated porcelain tiles for outdoor decks and driveways.

5.2 UAE & Wider Middle East

- Demand for glossy and polished finishes in high-end retail and hospitality.

- Large format vitrified tiles 600×1200 matte finish and polished porcelain are common.

- Climate:

- Extreme heat + occasional temperature swings.

- Focus on low water absorption tiles and R11 slip resistant tiles for wet public areas.

5.3 Europe (EU, UK)

- High importance on EN 14411 European standard tiles, CE marking and sustainability.

- Spain & Italy dominate premium segments, but India is competitive in value-for-money porcelain tiles and vitrified tiles.

- Demand:

- Outdoor porcelain tiles, textured floor tiles, eco-friendly sustainable ceramic tiles export, and large format tiles for minimal grout lines.

5.4 Australia

- Strong growth in indoor–outdoor design integration.

- Preference for textured non-slip tiles for patios, pool surrounds and alfresco spaces.

- Importers look for:

- AS4586 slip resistance reports.

- Non-slip tile R13 for pools and high P-rating products.

5.5 Other Growth Markets

- Canada, Mexico & Latin America, Saudi Arabia, Kuwait, Oman, Iraq, Russia – all expanding ceramic and porcelain tile consumption.

- Buyers are increasingly asking for:

- ISO-certified ceramic tile manufacturers

- SGS testing for ceramic tiles or other third-party tile inspection protocols

6. Packing, Palletization & Container Loading for Tile Exports

6.1 ISPM-15 & Pallet Choices

- ISPM-15 compliant pallets (heat-treated, HT stamped) are mandatory for most destinations (USA, EU, Australia, China, etc.).

- Pallet types:

- Wooden pallets: Most common and cost-effective for tile exports.

- Two-way entry / Four-way entry pallets: Four-way preferred for easier handling in warehouses.

- Common pallet sizes:

- 120 x 100 cm

- 120 x 120 cm

6.2 Internal Packaging

- Corrugated boxes with foam/paper cushioning.

- Plastic corner guards to protect edges.

- Moisture barrier (plastic wrap) around the entire pallet.

- Clear back-of-box print:

- Product name

- Size & thickness

- Quantity & total sqm

- Weight

- Grade (AAA, commercial grade)

- Batch / shade details

6.3 Container Loading Data (20ft Standard Container)

Approximate capacities:

- 10 mm tiles: ~800–820 sqm

- 12 mm tiles: ~650–670 sqm

- 18 mm tiles: ~460–500 sqm

- 20 mm tiles: ~440–470 sqm

- 30 mm tiles: ~270–300 sqm

General guidelines:

- Maximum payload: around 21.7 MT for a standard 20 ft container.

- Many USA shipments target ~21 MT; many European shipments can go higher (up to 24 MT, depending on route and regulations).

- Configurations:

- 10–11 pallets per 20-ft container in most cases.

- Floor-loaded configurations for large slabs, with extra cushioning and dunnage.

For container loading optimization tiles, Scalane International designs loading plans that balance sqm, weight and safety, minimising damage risk while maximising commercial value per container.

7. Common Problems Importers Face (Warpage, Shade, Flatness, Breakage) & Solutions

7.1 Warpage, Lippage & Flatness Issues

Typical complaints:

- “Tiles are not flat; installers see lippage.”

- “Large format porcelain tiles warp after installation.”

Root causes:

- Incomplete firing or uneven heating.

- Excessive warpage within a batch.

- Poor substrate preparation.

Solutions:

- Demand warpage measurement standards compliance (ISO 10545-2).

- Ask for warpage test data with actual values, not just “OK”.

- Require large format tile installation guidelines mentioning:

- Substrate flatness requirements

- Maximum allowable lippage

- Recommended trowel and leveling systems

7.2 Shade Variation & Batch Inconsistency

Typical complaints:

- “Shade variation issues batch-to-batch.”

- “Tiles on site don’t match approved sample.”

Solutions:

- Use shade variation grading V1–V4 in all offers.

- Insist on production batch tracking documentation.

- Keep approved control sample at the factory and at the importer side.

- For large orders, request AQL-based quality control sampling and third-party tile inspection protocols.

7.3 Water Absorption & Freeze-Thaw Failures

Typical problems:

- Tiles cracking after freeze-thaw cycles.

- Moisture ingress and mold in cold/humid climates.

Solutions:

- For outdoor and cold climates, use porcelain tiles <0.5% water absorption export only.

- Request freeze-thaw resistance testing protocols (ASTM C1026, EN tests).

- Include thermal expansion tiles data in technical submissions.

7.4 Slip Resistance & Safety Claims

Typical problems:

- Poor slip resistance on new tiles.

- Accidents in wet areas leading to liability issues.

Solutions:

- Ask for DIN 51130 slip resistance classification and AS4586 slip resistance test reports.

- Choose anti-slip ceramic tiles for commercial kitchens, R11+, P4–P5.

- Use textured tiles for slip resistance in bathrooms, pool areas, and outdoor walkways.

7.5 Breakage, Chipping & Transport Damage

Typical problems:

- Tiles breaking during shipping.

- Chipping edges and corner damage on arrival.

Solutions:

- Improve internal packaging (foam, cardboard dividers, corner guards).

- Ensure ISPM-15 pallet certification and correct pallet handling.

- Use moisture barrier packaging tiles for long sea voyages.

- Implement pre-shipment inspection checklist tiles focusing on packing, strapping and pallet condition.

8. Testing & Documentation Checklist (ISO, DIN, AS 4586, CE, ANSI) Vitrified Tiles vs Porcelain tiles

8.1 Essential Technical Test Certificates

- ISO 10545-3: Water absorption test (critical for porcelain vs vitrified tiles).

- PEI rating test for glazed products.

- Slip resistance testing standards:

- DIN 51130 R9–R13

- AS 4586 P0–P5

- DIN 51097 for barefoot areas https://www.din.de/en

- Breaking strength and modulus of rupture testing.

- Freeze-thaw cycling test procedure results for outdoor porcelain tiles.

- Crazing resistance, chemical resistance, stain resistance classification.

8.2 Safety & Regulatory Documentation

- Safety data sheet ceramic tiles / SDS for crystalline silica.

- OSHA-compliant respiratory warnings for cutting and drilling porcelain tiles.

- Product liability insurance for major markets.

- ISO 13006 compliance tiles, EN 14411, ANSI A137.1 USA standard tiles, and CE marking documentation where applicable.

Scalane International provides a complete technical documentation pack tailored to each destination’s building code tile requirements.

9. India vs China vs Spain vs Italy vs Turkey – Competitor Technical Benchmark

9.1 India vs China

- Finish quality: India – consistent polished and lappato finishes, strong digital printing. China – extremely wide range, from basic to premium.

- Technical strength: China leads in volume and automation; India leads in consistency and reliability for porcelain and vitrified tiles with strict ISO 13006 norms.

- Slip ratings & safety: Indian factories increasingly invest in DIN 51130 R9 R10 R11 R12 R13 and AS4586 slip resistance test reports.

- Water absorption: India offers low water absorption tiles with tight control for export.

9.2 India vs Spain

- Spain: Benchmark in premium polished finishes, museum-level glazing, strong environmental credentials.

- India: Slightly lower in “luxury perception” but much stronger on value-for-money porcelain tiles.

- Slip & safety: Spain typically has the strictest enforcement; Indian high-end factories match these requirements on project basis.

9.3 India vs Italy

- Italy: The global luxury leader for porcelain tiles, design innovation, and artisanal finishes.

- India: Strong in mass-market innovation, large format tiles and competitive export offerings for developing markets.

9.4 India vs Turkey

- Turkey: Combines traditional patterns with modern porcelains, often very competitive in regional markets.

- India: Offers wider range and higher installed capacity, plus better consistency in technical data and batch quality at scale.

Bottom line for importers:

India is increasingly the sweet spot between technical performance, design variety, and commercial viability for porcelain tiles and vitrified tiles in 2025.

10. FOB Export Structures for Vitrified Tiles vs Porcelain tiles

Although we will not discuss any tile cost here, it is still important to understand how FOB-based exports are typically structured.

10.1 Typical FOB Tile Export Scenario for Vitrified Tiles vs Porcelain tiles

For example, an importer orders:

- 600×600 glazed porcelain tiles,

- 10 mm thickness,

- PEI 4, R10, water absorption <0.5%,

- Surface: matte or lappato,

- Destination: USA, Europe, Middle East or Australia.

Scalane International:

- Packs and loads approximately 800–820 sqm per 20-ft container depending on design mix.

- Ensures all pallets are ISPM-15 compliant.

- Prepares full export documentation tiles including testing reports, packing lists and certificates.

- Provides clear breakdown of FOB terms (port, container configuration, documentation, QC responsibilities).

Similar structures apply for:

- Vitrified tiles 600×1200 matte finish supplier orders.

- Double-charged vitrified tiles or full-body porcelain tiles for commercial projects.

For global buyers choosing between vitrified tiles vs porcelain tiles, Scalane International provides verified technical data and export support

11. FAQ: Vitrified Tiles vs Porcelain Tiles – Technical Buyer Questions

Q1. What is the difference between porcelain and ceramic tiles?

Porcelain tiles use more refined raw materials, are fired at higher temperatures (around 1200°C+), and have water absorption ≤0.5%, making them denser and more durable. Standard ceramic tiles have higher water absorption and are best suited to walls and low-traffic floors.

Q2. Are vitrified tiles better than ceramic floor tiles?

Yes, for floors and export projects, vitrified tiles usually outperform basic ceramic floor tiles:

- Lower water absorption (0.5–1.0% vs 3–7%+).

- Better abrasion resistance (higher PEI).

- More consistent performance for residential and light commercial floors.

Q3. When should importers choose porcelain tiles over vitrified tiles?

Choose porcelain tiles when:

- You need freeze-thaw resistant tiles for cold climates.

- You supply outdoor porcelain tiles or non-slip tile R13 for pools.

- You target heavy commercial projects where PEI 4–5, high MOHS hardness and robust performance are critical.

Q4. How is water absorption measured in tiles?

Water absorption is measured according to ISO 10545-3:

- Tiles are dried, weighed, immersed and reweighed.

- The percentage increase in weight due to absorbed water determines the water absorption class.

Q5. What is PEI rating and why does it matter?

The PEI rating measures glaze surface abrasion resistance. Higher PEI ratings (4–5) indicate a tile can withstand heavier foot traffic, making it suitable for commercial floor tiles.

Q6. What causes tile warpage?

Tile warpage can result from:

- Uneven shrinkage during firing.

- Inconsistent raw material mix.

- Excessive tile size with insufficient firing control.

That’s why buyers must check warpage measurement standards, lippage calculation and tolerance, and insist on rectified tiles from stable production lines.

Q7. Why are large format tiles harder to install?

Large format tiles (e.g. 600×600 porcelain tiles, 800×800 ceramic tiles, slabs) magnify:

- Substrate unevenness.

- Warpage and lippage.

Installers must follow large format tile installation guidelines and use suitable levelling systems and expansion joints.

Q8. What is lappato finish compared to glossy?

- Lappato tiles: Semi-polished, a balance between matte and glossy, with soft reflections and better practical slip resistance.

- Glossy tiles: High-shine, reflective surfaces, great for walls and dry areas but more slippery when wet.

Q9. Which tiles are best for commercial kitchens?

- Anti-slip ceramic tiles for commercial kitchens or porcelain tiles with:

- R11–R13, P4–P5 slip ratings

- Chemical resistant tiles, stain resistant tiles

- PEI 4–5, high MOHS hardness. Understanding vitrified tiles vs porcelain tiles is essential when comparing water absorption and PEI ratings

Q10. How should tiles be packaged for export?

Key points:

- ISPM-15 certified pallets.

- Boxes with internal cushioning and corner guards.

- Moisture barrier wrap.

- Clear labelling with batch, shade, size and weight.

- Careful container loading requirements tiles to avoid overloading and damage.

12. How Scalane International De-Risks Tile Imports

At Scalane International, the goal is simple:

Help importers, distributors, and project buyers win their market with technically strong, export-ready porcelain tiles and vitrified tiles.

What Scalane International Brings to the Table

- ISO-certified manufacturing partners with strong track record in porcelain tiles, vitrified tiles and digital printing tile technology.

- Detailed porcelain tile technical data, ceramic tile specification sheets and full test reports.

- Market-specific recommendations for USA, Middle East, Europe, Australia and beyond.

- Strong focus on warpage-free flat tiles, batch consistency, slip resistance, and freeze-thaw performance.

- Optimised container loading and packing specifications to minimise breakage and claims. This 2025 guide clearly explains vitrified tiles vs porcelain tiles for global buyers.

- Request the latest Porcelain & Vitrified Tile Catalogue

Get a full product catalogue with technical data:- Water absorption, PEI, MOHS hardness

- R and P slip ratings

- Thickness and size options (600×600, 800×800, 600×1200, slabs)

- Ask for Technical Samples & Mock-Ups

Send project requirements (indoor, outdoor, commercial, climate) and receive:- Targeted tile samples

- Shade and surface finish mock-ups

- Technical data packs and test certificates

- For catalogue requests, visit Scalane International’s contact page.

- Book an Export Strategy Call

Discuss:- Target market (USA/EU/Middle East/Australia/others)

- Best-fit porcelain vs vitrified tiles for your climate and segment

- Optimal container loading plan and technical documentation roadmap